Leave Your Message

-

Telephone

-

WeChat/ WhatsApp

-

Email

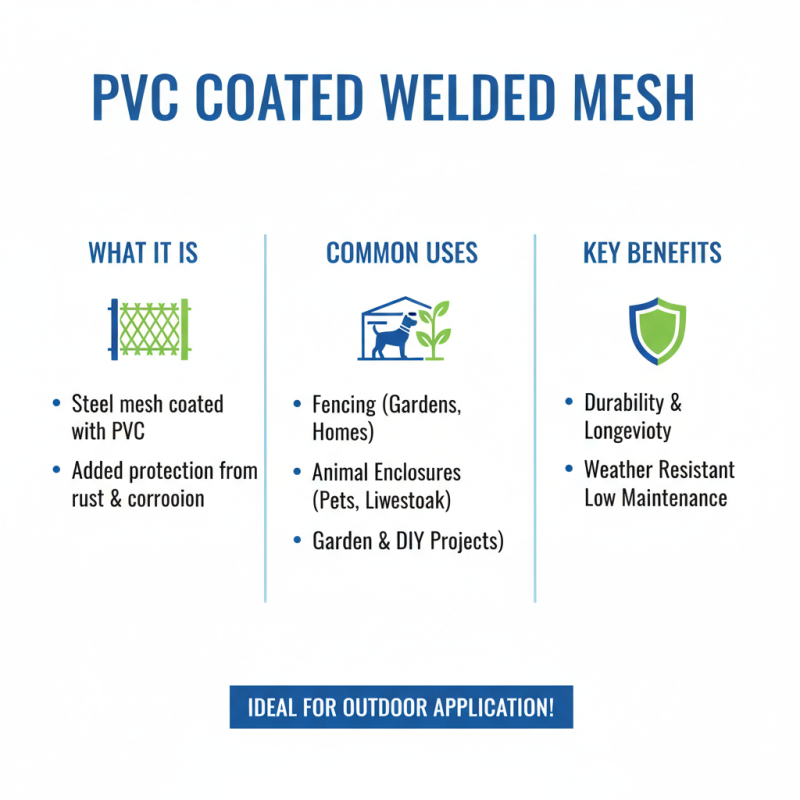

Choosing the right PVC Coated Welded Mesh can seem overwhelming. With various options available, it’s essential to consider your specific needs. This mesh type offers durability and versatility, making it suitable for many applications.

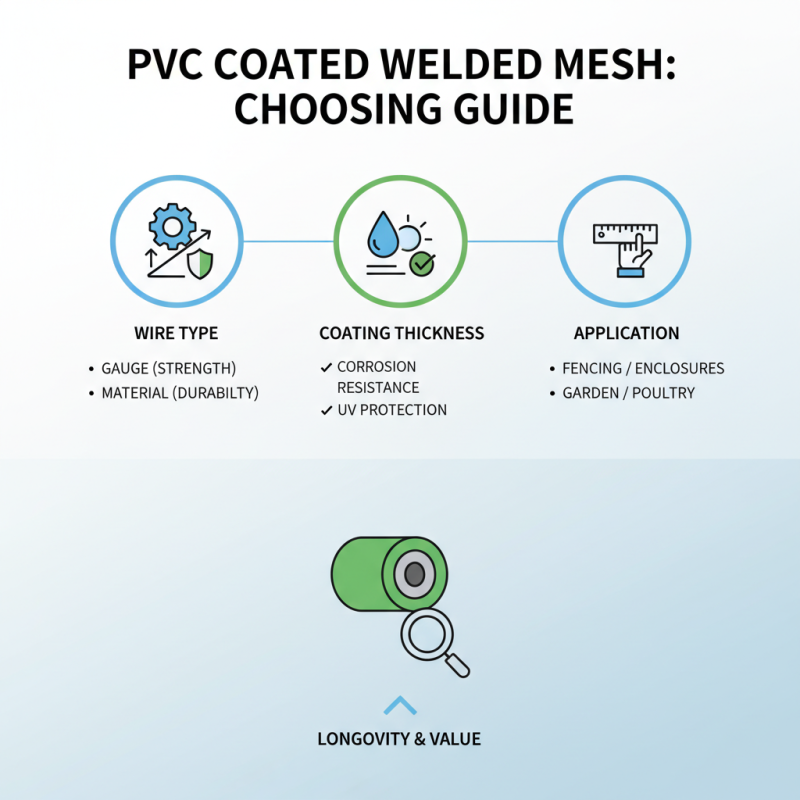

When selecting PVC Coated Welded Mesh, think about the environment. Does it need to withstand harsh weather? Ensure that the coating can resist corrosion and UV damage. Also, the wire gauge and spacing influence the strength and security of the mesh. A thicker wire often provides better support.

Consider the aesthetics as well. PVC comes in different colors, enhancing visual appeal. This aspect can be crucial for outdoor projects. However, not all colors may provide the same UV protection. Take your time to compare options and reflect on what truly suits your project requirements. Choosing the ideal PVC Coated Welded Mesh is about balancing functionality with preference.

PVC coated welded mesh is a versatile material. It is commonly used in various applications, such as fencing, animal enclosures, and garden projects. The coating provides extra protection against rust and corrosion. This makes it an ideal choice for outdoor use. However, not every mesh suits all needs.

When selecting PVC coated welded mesh, consider the wire diameter and mesh size. Thicker wires offer more strength, but they might be harder to work with. Additionally, larger mesh openings can be more functional for specific projects, but they may not provide the same level of security. Think about the potential challenges. Sometimes, the options can be overwhelming.

Tips: Always check the UV resistance of the PVC coating. This ensures that the mesh lasts longer in sunlight. It’s wise to assess the environment where you plan to install the mesh. For example, areas with heavy snowfall may require a different gauge than those in mild climates.

Evaluating your project’s demands is crucial. What works for one situation may not work for another. Take time to envision how the mesh will fit into your plans. Reflect on the durability and aesthetics that truly matter to you.

When choosing PVC coated welded mesh, several key factors come into play. The type of wire used is essential. Look for different wire gauges that offer varied strength and durability. Lighter gauges may seem appealing for cost-effectiveness, but they could lack the necessary sturdiness. Consider the thickness of the PVC coating, too. A thicker coat provides better protection against corrosion and UV rays, ensuring longevity.

The mesh size is another critical aspect. Smaller openings may offer better security, yet they can limit visibility. This trade-off is vital to consider based on your specific application. Additionally, evaluate the intended use. Is it for gardening, security, or maybe animal enclosures? Different environments may require different strengths and coatings. Don't overlook the installation process. Some types may be easier to work with than others. Reflect on your skills and available tools; complexity can add unforeseen challenges.

When selecting PVC coated welded mesh, durability is a primary concern. A strong mesh can withstand harsh conditions. It’s essential to assess both the coating and the wire gauge. Thicker wires generally offer better strength and resistance to bending. Look for a coating that can resist moisture and corrosive elements. A high-quality PVC layer provides a protective barrier, enhancing longevity.

Resistance to UV rays is another aspect to evaluate. Mesh exposed to sunlight can deteriorate over time. Consider additional features like anti-fungal properties. This can be crucial if the mesh is used in humid environments. Test samples, if possible, to check how they hold up under daily wear.

Choosing the best mesh often involves trial and error. You may find one type meets your needs initially, but not over time. Be prepared to rethink your choices. Gather feedback from others who have used certain meshes. Their experiences can reveal hidden flaws. Weigh these insights against your requirements for a balanced decision.

This chart evaluates the durability ratings of various types of PVC coated welded meshes based on their specific properties. The ratings are indicative of their performance in terms of durability and resistance, helping you make an informed decision.

When selecting PVC coated welded mesh, size is a crucial factor. Measure the area where you plan to use it. If it's for security fencing, a taller height can deter intruders. For gardening, a shorter fence may suffice. Consider how the mesh fits into your existing space. A good fit is vital for effectiveness.

Gauge, which refers to the thickness of the wire, also matters. Thicker gauges tend to be more durable. However, they are heavier and can be harder to install. A lighter gauge may be more manageable but might not withstand harsh weather conditions. Determine the balance between strength and ease of handling.

Mesh opening size impacts what can pass through it. Smaller openings will keep out small animals, while larger openings may be suitable for larger pets. Think about your specific needs. A wrong choice can lead to issues later. Reflect on what you need most. Will you require flexibility or strength? Each choice has its trade-offs. Take time to weigh your options.

When selecting PVC coated welded mesh, the balance between cost and quality is vital. Industry reports indicate that high-quality PVC can enhance durability by up to 30%. However, cheaper options may wear down faster, leading to higher long-term costs.

Understanding your specific needs is crucial. If your project demands resilience, investing in premium materials is wise. Look for mesh with a thicker coating. This can significantly resist corrosion. Yet, it’s essential to weigh this against your budget.

Tip: Prioritize projects where durability truly matters. For less demanding applications, a more affordable option could suffice. Remember, quality often correlates with performance. A mesh panel that costs a little more upfront may save you from frequent replacements later.

Tip: Always request product samples before making a bulk purchase. This helps you gauge thickness and flexibility. Not all products meet the same standards, and firsthand experience can reveal flaws not evident in brochures.

| Feature | Low-End Options | Mid-Range Options | High-End Options |

|---|---|---|---|

| Material Thickness | 1.0 mm | 1.5 mm | 2.0 mm |

| Coating Thickness | 25 µm | 50 µm | 75 µm |

| Aperture Size | 25 mm x 25 mm | 20 mm x 20 mm | 15 mm x 15 mm |

| UV Resistance | Low | Medium | High |

| Expected Lifespan | 2-5 years | 5-10 years | 10-20 years |

| Approximate Cost per Square Meter | $10 | $20 | $35 |