Leave Your Message

-

Telephone

-

WeChat/ WhatsApp

-

Email

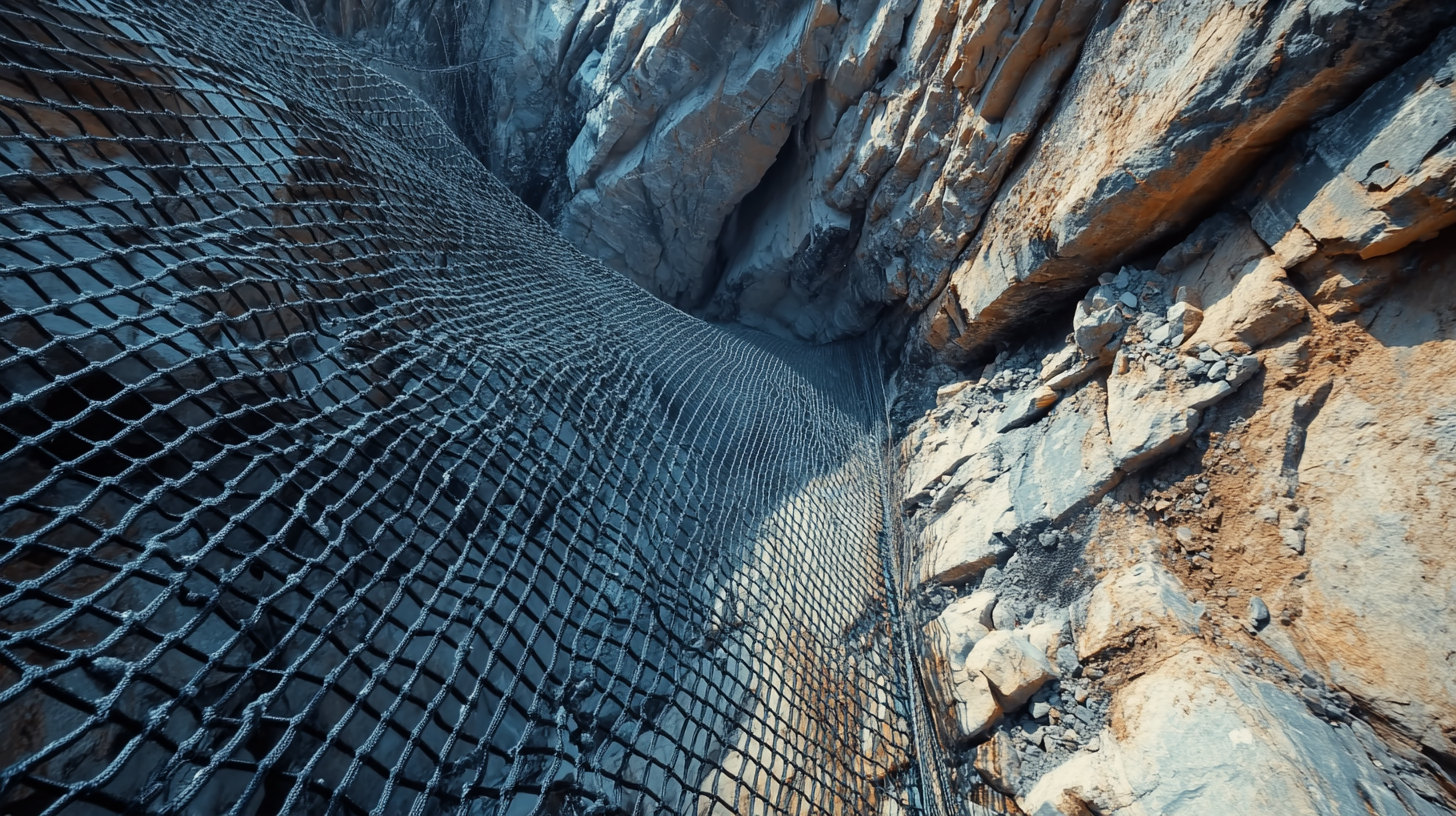

In the ever-evolving landscape of construction and safety, Rockfall Barrier Netting has emerged as a critical component for protecting both people and infrastructure from potential landslides and rockfalls. As global buyers seek unmatched reliability and performance, they often turn to China's leading factories, renowned for their advanced manufacturing techniques and rigorous quality control. These factories not only prioritize safety and durability but also embrace innovative technologies to enhance the effectiveness of their Rockfall Barrier Netting solutions. This blog explores the integral role of these manufacturing giants in the global market, shedding light on their commitment to delivering high-quality products that meet international standards and the specific needs of diverse terrains. By examining their production processes and the benefits of their offerings, we aim to provide valuable insights for buyers looking to invest in dependable Rockfall Barrier Netting solutions.

In modern engineering projects, the significance of rockfall barrier netting cannot be overstated. As highlighted by the International Society for Rock Mechanics, falling rocks pose a considerable risk to infrastructure, particularly in mountainous regions. The implementation of effective rockfall barrier systems can mitigate potential damage, ensuring the safety of both personnel and equipment. Reports indicate that well-designed barrier systems can reduce rockfall impact forces by up to 70%, showcasing their crucial role in safeguarding assets and human lives.

Tips for optimal installation and maintenance of rockfall barrier netting include conducting thorough geological assessments prior to implementation. Identifying potential rockfall zones and the size of falling debris can significantly influence the selection of netting materials and design. Additionally, regular inspections and maintenance of installed systems can enhance their longevity and effectiveness. Engaging experienced engineers familiar with local geological conditions can also improve project outcomes and ensure compliance with safety standards.

The selection of high-quality rockfall barrier materials is essential to withstand harsh environmental conditions. Research from the Geoengineering Research Society suggests that using robust, weather-resistant netting materials can extend the operational lifespan of barriers. By investing in superior products, global buyers can ensure unmatched reliability in rockfall protection, ultimately leading to safer and more resilient projects.

The demand for high-quality rockfall barrier solutions is witnessing a significant increase globally. As industries recognize the importance of safety measures, the need for reliable rockfall barrier netting has surged. This trend is evident in various sectors, including construction, mining, and tourism, where rockfall incidents pose substantial risks. Key industry statistics reflect this growing demand, with more companies investing in robust safety solutions to protect their assets and personnel.

Notably, markets like North America are seeing a parallel growth in safety equipment, including industrial safety footwear, which is projected to reach USD 19.28 billion by 2033. This indicates a broader shift towards stringent safety protocols across industries. As global buyers look for unmatched reliability in rockfall barrier solutions, manufacturers in China are poised to meet this demand, offering innovative products tailored to enhance safety measures in challenging environments. The synergy between rising safety demands and advanced manufacturing capabilities is set to redefine standards in the rockfall barrier industry.

China has emerged as a powerhouse in the production of rockfall barrier netting, driven by advanced technology and a commitment to quality. The country’s leading factories utilize state-of-the-art equipment and innovative manufacturing processes that ensure the durability and effectiveness of their products. This unmatched reliability has made Chinese manufacturers the preferred choice for global buyers seeking robust solutions to mitigate rockfall hazards.

In addition to cutting-edge production techniques, Chinese factories are bolstered by an experienced workforce skilled in crafting high-performance netting systems. The seamless integration of design and functionality in these products reflects the factories’ dedication to meeting international safety standards and client specifications. As the demand for rockfall barrier netting grows, particularly in mountainous regions prone to landslides, China's factories stand ready to provide innovative, reliable, and cost-effective solutions that enhance safety and sustainability worldwide.

The advancements in materials used for rockfall barrier systems mark a significant leap in engineering safety solutions for roads and highways. With growing global concerns over the safety of transportation infrastructure, innovations in geosynthetics and specialized steel products are at the forefront of enhancing the durability and effectiveness of these systems. According to a report by the Global Geosynthetics Market, the demand for high-performance materials is expected to grow by 10% annually, highlighting the critical need for robust solutions that mitigate rockfall hazards.

Recent insights from industry leaders emphasize that material innovations, such as the integration of advanced polymers and steel alloys, significantly improve the lifespan and resilience of rockfall barriers. For instance, the use of high-tensile wires in barrier nets can reduce maintenance costs by 25% while ensuring compliance with stringent safety regulations. Moreover, these technologies are also designed to adapt to varying geological conditions, offering tailored solutions for specific risks. As global buyers seek reliable protection systems, the evolution of rockfall barrier netting represents a response to both environmental challenges and infrastructural integrity, supporting safer travel for communities worldwide.

Rockfall barrier netting has emerged as a critical solution for managing geological hazards, particularly in mountainous regions vulnerable to landslides and rockfalls. Case studies from various countries highlight the effectiveness of these systems. For instance, a report by the International Journal of Rock Mechanics and Mining Sciences noted that rockfall barriers successfully reduced incident frequencies by over 70% in certain high-risk areas, significantly enhancing safety for both infrastructure and local communities.

In Italy, the successful implementation of rockfall netting along key alpine routes demonstrated a marked improvement in road safety. Following the installation of these barriers, incidents of rockfall-related accidents decreased by 65% within the first year. Furthermore, a project in the Swiss Alps reported that enhanced rockfall protection allowed for a reduction in maintenance costs by 30%, enabling local governments to allocate resources more effectively. As global demand for reliable safety solutions continues to grow, these case studies not only reflect the technology's capabilities but also emphasize the economic and social benefits it provides across different environments.

| Case Study | Location | Implementation Year | Netting Type | Results |

|---|---|---|---|---|

| Yosemite National Park | USA | 2020 | Steel Wire Netting | Significant reduction in rockfall incidents, improved visitor safety. |

| Andes Mountain Range | Chile | 2019 | Polyester Netting | Protected infrastructure, enhanced stability of slopes. |

| Japanese Alps | Japan | 2021 | High-Strength Wire Netting | Successfully contained rockfall, protecting local communities. |

| Alps Tunnel Project | Switzerland | 2018 | Composite Netting | Minimized maintenance costs, improved operational safety. |